Who We Are | What We Do

CNC Engraving Machine Manufacture

We are CNC Engraving Machine Manufacturer based in India. Our CNC Milling & Engraving Machine are economical and suitable for making high precision molds & components.

We manufacture wide range of products with unmatched industry expertise. As a result, it enables our customers meet their challenges in 3-axis, 4-axis and 5-axis CNC milling and engraving applications.

All our product range is developed keeping in mind quality, durability and consistency. First of all, we believe in developing technology that increases the profitability for each customer’s business. Furthermore as a CNC Engraving Machine Manufacturer we focus on providing customer’s with true value for their investment.

We provide complete end-to-end solution of CNC Milling Machine or Engraving Machine including machine tool, machine operating and software with training.

We have manufactured and supplied CNC Milling Machine / Engraving Machine for various industries mentioned below:

High Performance CNC Machine

12

YEARS OF EXPRIENCE

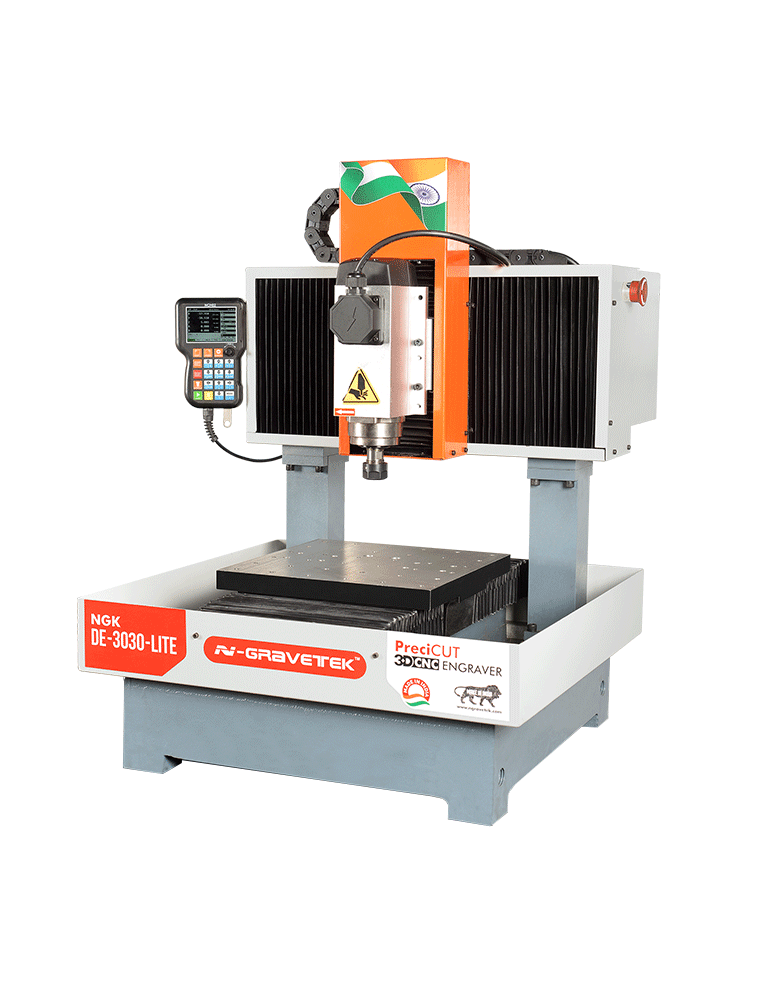

PrecitCUT

PrecitCUT is a cutting-edge precision engineering company that specializes in offering high-quality cutting solutions to clients across various industries. With decades of experience in the industry, the company has established itself as a trusted and reliable partner for businesses that require accurate and precise cutting services.

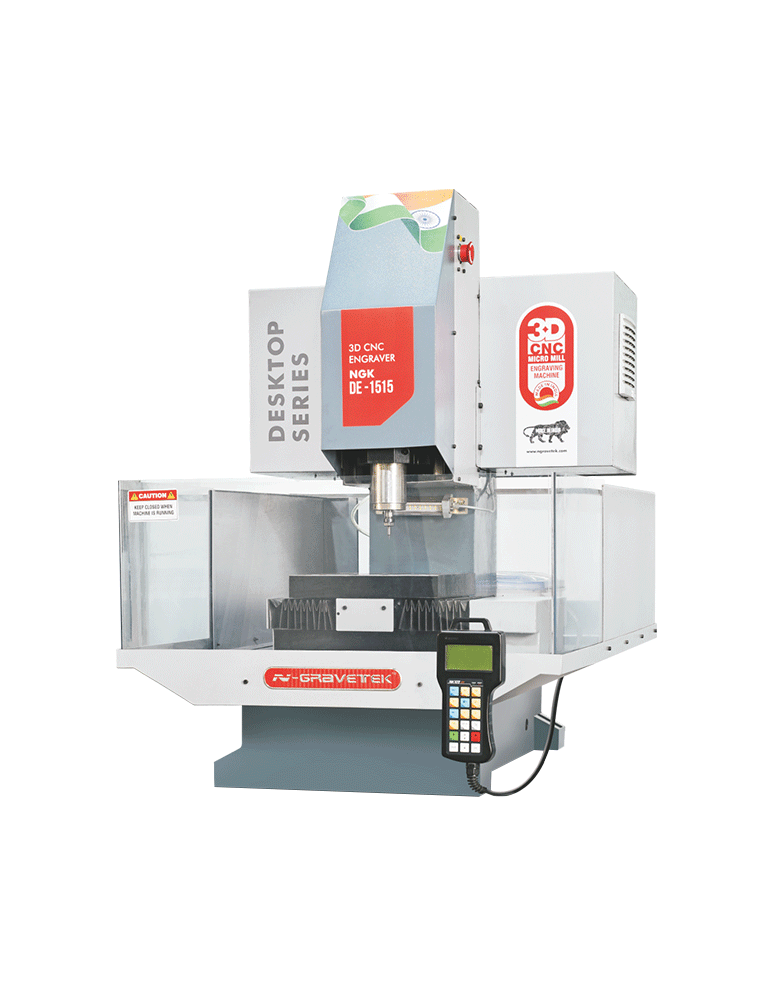

DESKTOP SERIES - NGK-DE(S)-1515

DESKTOP SERIES - NGK-DE(S)-1515 is a state-of-the-art computer numerical control (CNC) machine designed for precision machining tasks. This compact desktop-sized CNC machine is perfect for small-scale production, prototyping, and educational purposes.

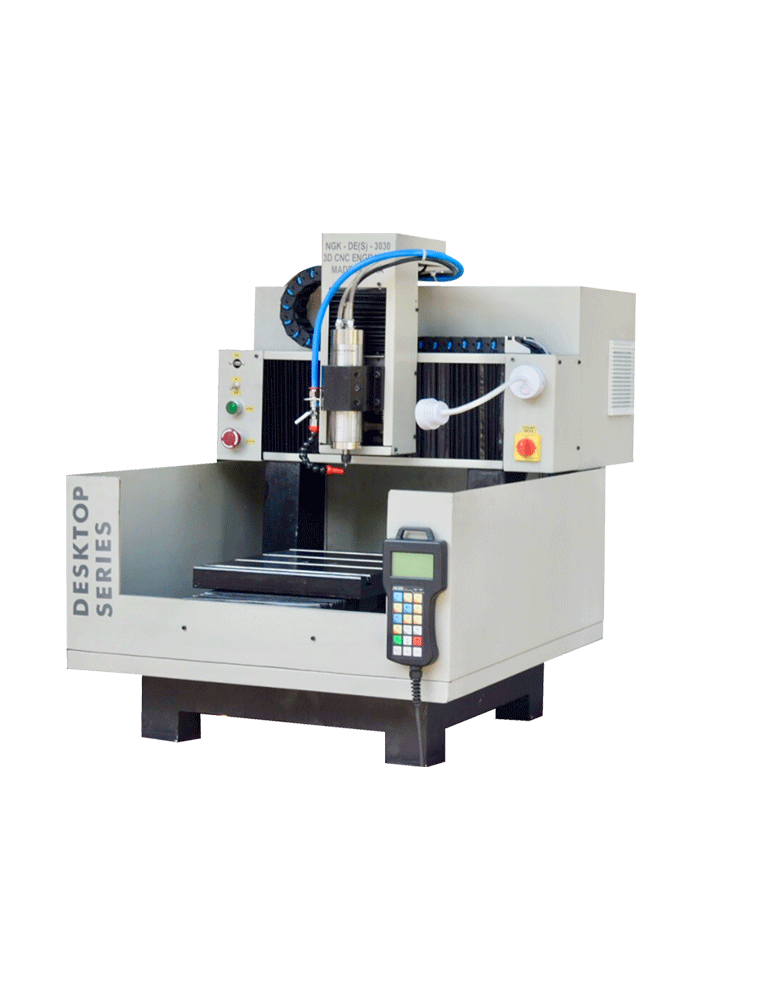

DESKTOP SERIES - NGK-DE(S)-3030

The DESKTOP SERIES - NGK_DE(S)-3030 is a compact and versatile computer numerical control (CNC) machine designed for precision cutting and carving of a variety of materials. This powerful desktop machine features a durable and robust frame, high-speed spindle motor, and precision linear guide rails for smooth and accurate movement.

ECO SERIES - NGK-ECO(S)-3030

ECO SERIES - NGK-ECO(S)-3030 is an advanced and eco-friendly CNC machine that combines precision engineering with sustainable design. This state-of-the-art CNC machine is designed to provide efficient and precise machining while reducing energy consumption and minimizing environmental impact.

PRO SERIES - NGK-PRO(S)-3030

PRO SERIES - NGK-PRO(S)-3030 is a high-performance spark plug designed to deliver maximum power and efficiency to your engine. Made by NGK, a leading manufacturer of automotive spark plugs, this plug is designed to meet the demands of professional racers and enthusiasts alike.

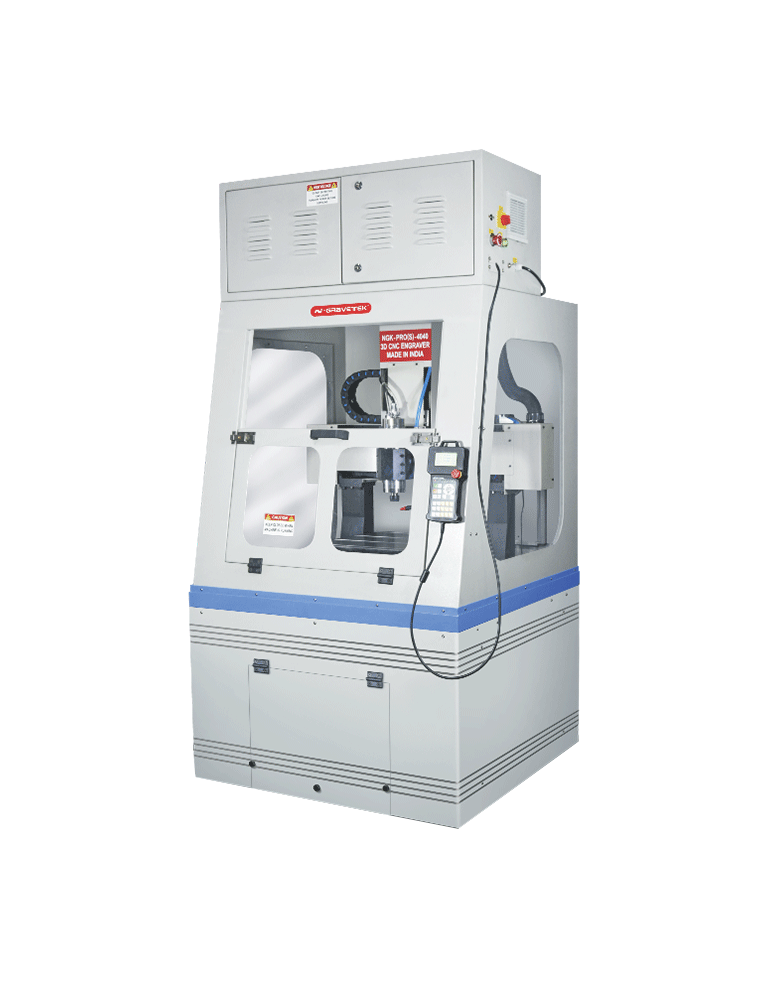

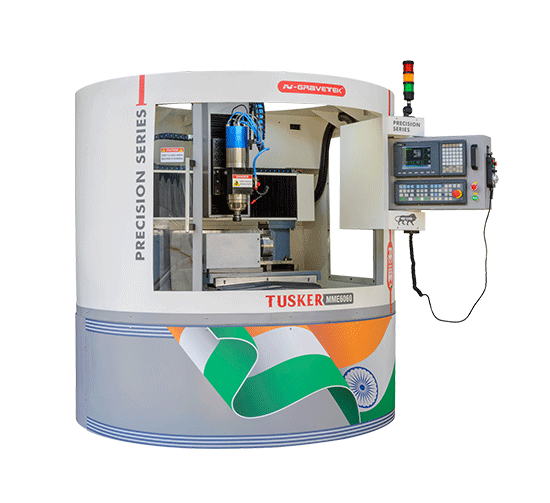

PRECISION SERIES - NGK-MME-4040

Precision Series NGK-MME-4040 is a high-performance website that showcases the innovative and reliable capabilities of NGK's cutting-edge engineering technology. The website is dedicated to the NGK-MME-4040, an advanced motion control system that provides precise and accurate movement control for industrial automation applications.

QUALITY

Firstly, as CNC Machine Manufacturer we focus on quality. Secondly, our aim is to develop technology that increases the profitability for each customer. Thirdly, our team provides good customer support with less turn-around time. In conclusion, we want our customers to get true value for their investment from a trusted CNC Machine Manufacturer.

Each and every part we manufacture is scrutinised and goes under thorough inspection by our quality control department. We calibrate our products to get precise results with high accuracy.

Each and every machine manufactured goes under quality tests. Standard programs along with customer application specific tests are executed on the machine. The products are delivered to the customers only after they have cleared all the quality tests and customer is satisfied with the results of jobs realised for their application.

WHAT CUSTOMER SAY

Testimonials

CONTACT US

GET IN TOUCH.

Lorem ipsum dolor sit am adipi we help you ensure everyone is in the right jobs sicing elit, sed do consulting firms Et leggings across the nation tempor Lorem ipsum dolor